Liquid-Liquid Coalescers

THE BEST PARTNER HANBIT SOLTECH

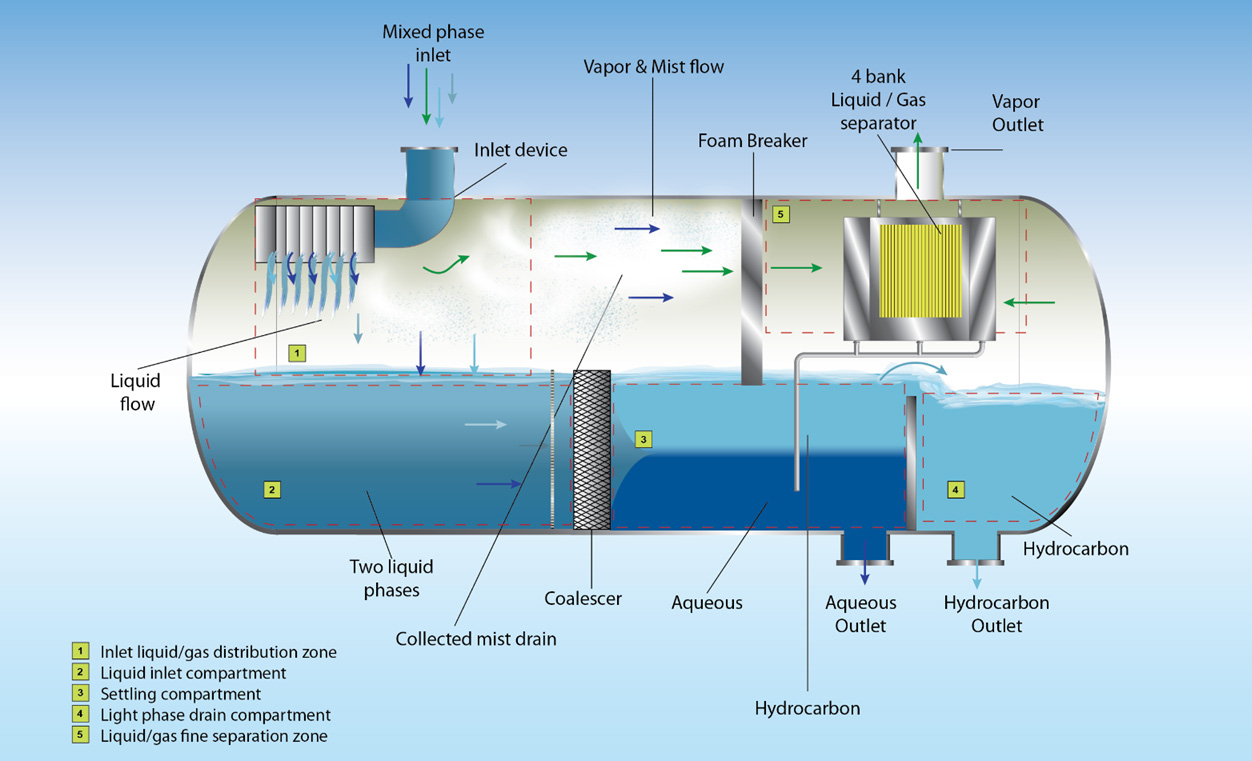

If the specific gravity of the dispersed phase is greater than that of the continuous phase (i.e., aqueous-from-hydrocarbon separation), the coalesced droplets settle downward by gravity and are collected at the bottom of the vessel. Conversely, if the specific gravity of the dispersed phase is less than that of the continuous phase (i.e., hydrocarbon-from-aqueous separation), the coalesced droplets are collected at the top of the vessel.

When surfactants are not present in an aqueous-hydrocarbon system, coalescing occurs spontaneously. Surfactants, however, can create a stable emulsion that cannot be separated without special equipment, such as a coalescer.

Protect downstream equipment

Coalescers separate sulfuric acid, caustic or water mixed with hydrocarbon streams to minimize the potential corrosion of downstream equipment.Reduce wastewater treating cost

Coalescers help reduce effluent contamination, which can reduce the burden on wastewater treatment facilities.Improve product quality

Coalescers efficiently remove a haze that causes off-specification products.Increase capacity and efficiency

Coalescers allow higher capacity compared to gravity settling alone by increasing allowable superficial velocities as well as improving separation efficiency.Minimize loss of valuable solvents

Coalescers minimize the loss of valuable solvents in liquid-liquid contacting towers such as LPG amine treaters.Plate Pack Coalescers

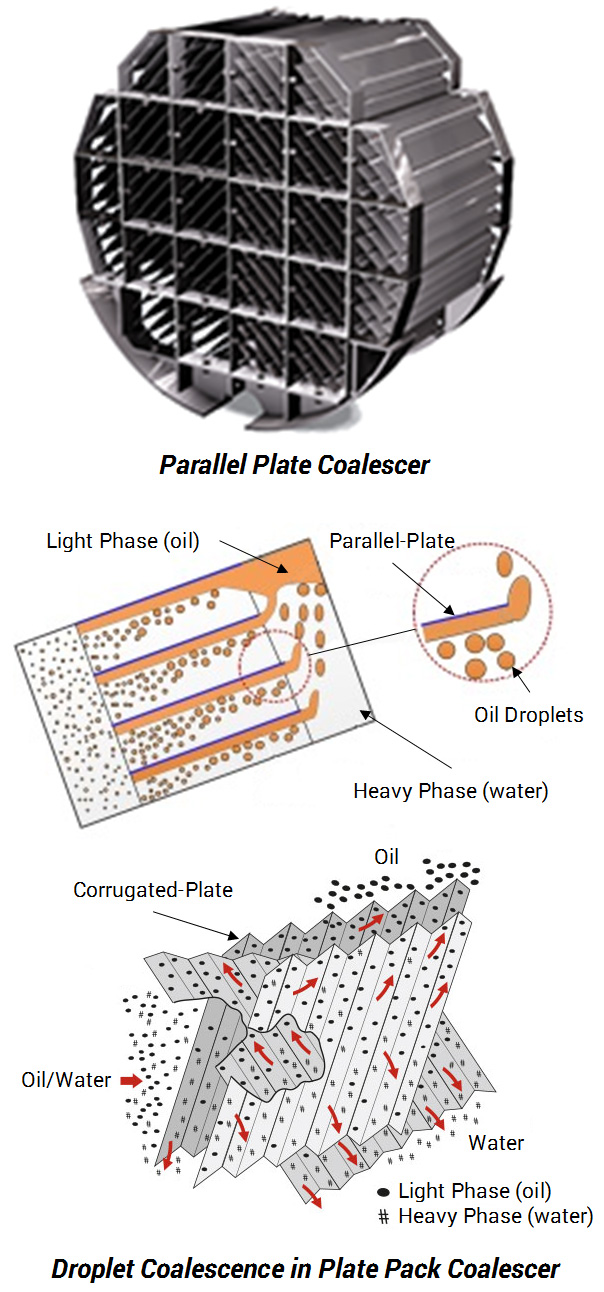

Plate pack coalescers are typically classified as either parallel-plate or corrugated-plate separator internals. These coalescers work on the principle of gravity settling. Parallel-plate coalescer is the best choice when there is concern about fouling or plugging from solid materials in the feed. If the feed stream is clean, a corrugated-plate coalescer is the better choice. It provides higher separation efficiency per unit of length compared to parallel-plate due to the larger specific surface area.

• Maintain efficiency even with phase inversion of dispersed liquid

• Mechanically durable construction

• Carbon Steel

• Nickel Alloys

• Titanium

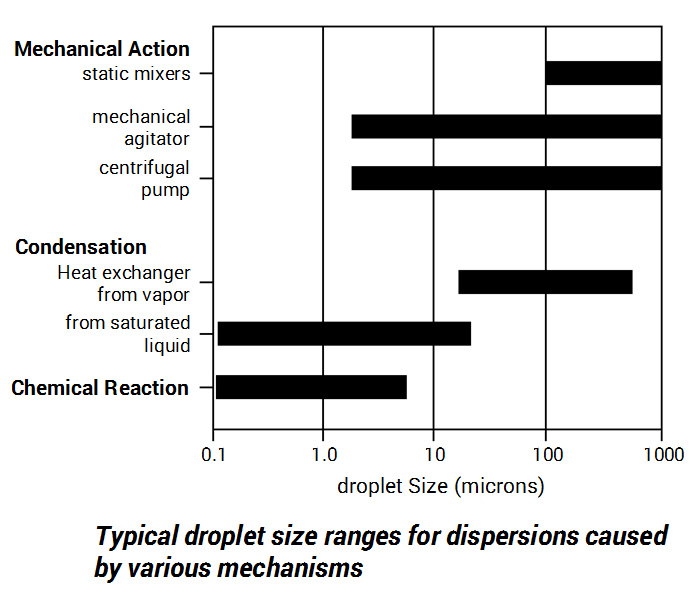

In cases where the droplet size is larger than 200 microns, it will settle quickly. However, smaller droplet dispersions require a lot of settling time when they have to travel a long distance to the interface.

With the use of plate pack coalescers, each plate provides many interfaces within the vessel. They promote coalescing work by reducing the distance that droplets rise or fall. While passing through the plate pack, the droplet dispersions grow rapidly. And then they settle to the primary interface in the vessel after exiting the plate pack.

Mesh Pad Coalescers

Mesh pad coalescers are used to achieve efficient phase separation where liquid dispersions are being processed. These coalescers are manufactured in the form of mesh pads with the desired thickness, density and surface area. The small droplets of a fine dispersion will be coalesced and enlarged by passing the dispersion through a mesh pad coalescer. And then the enlarged droplets will be settled more rapidly.

• Easy to install in all process equipment

• Most cost-effective solution

• Nickel Alloys

• Titanium

• Aluminum

• Copper

• Polypropylene

• Fluoroplastics

① Droplets are captured on filaments.

② Droplet coalescence begins and droplets move to filament intersections by liquid stream.

③ Coalescence of two droplets forms one larger droplet, and coalescence of small droplets into the larger droplets is repeated.

④ Ultimately, larger droplets are released from filaments by drag force of liquid stream.

⑤ Continuously repeat of steps ①-④.

The specific surface properties of the coalesce filaments are critical in the adherence of droplets and then coalescing.