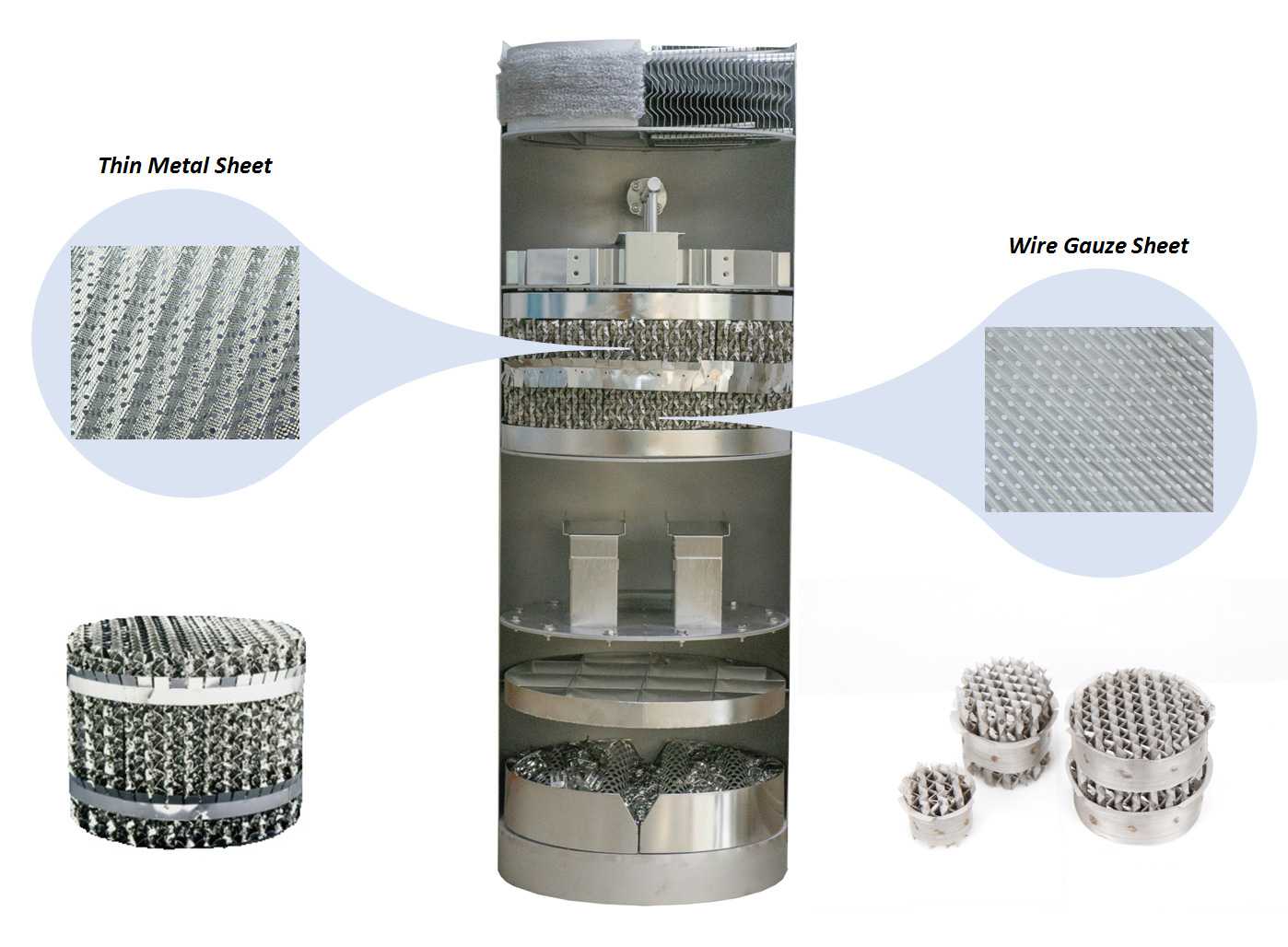

Structured Packings

THE BEST PARTNER HANBIT SOLTECH

Type and size of our structured packing is various with the crimp height, angles and specific surface area depending upon their applications.

HSP

Thin Metal Sheet Structured Packing

HSP corrugated structured packings are fabricated from thin, crimped metal sheets, arranged in parallel to each other. It has embossed and perforated surfaces. HSP is available in several types. The HSP number denotes the nominal surface area of the packing per unit volume. The suffix denotes the angle of orientation to the vertical axis; Y signifies 45°, X signifies 60°. Wall wipers are included with each element to minimize liquid and vapor bypassing along the column wall.

Due to the corrugations, vapor and liquid flow through a single element spreads in a series of parallel sheets. In order to spread the vapor and liquid uniformly in all radial sheets, each element is rotated at a certain angle with respect to the element below. In each element, corrugated sheets are inclined at 45° (or 60°) to the vertical. This angle is large enough for good drainage of liquid, avoiding stagnant pockets and regions of liquid accumulation, and small enough to prevent gas from bypassing the metal surfaces.

HSP corrugated structured packings have a enhanced surface that assists the lateral spread of liquid, and enhances the area available for mass transfer. The surfaces of structured packings contain perforations. The holes serve as communication channels between the upper and lower surface of each sheet.

High capacity 252Y is also available, which is similar in construction to standard 250Y packing except for a subtle modification in the geometry of the corrugation at the top and bottom of each packing layer to avoid increasing the pressure drop at layer interface.

• Provides maximum predictable fractionation efficiencies.

• Combines high capacity and low pressure drop per theoretical stage.

• Sheet surface texturing improves separation efficiency.

※ If the entire table is not visible, you can scroll the table left and right to check the entire table.

| Type | Inclination Angle | Surface Area, ㎡/㎥ |

|---|---|---|

| 125Y | 45° | 125 |

| 170Y | 45° | 170 |

| 2Y | 45° | 223 |

| 250Y | 45° | 250 |

| 250HC | 45° | 250 |

| 350Y | 45° | 350 |

| 350HC | 45° | 350 |

| 500Y | 45° | 500 |

| 125X | 60° | 125 |

| 170X | 60° | 170 |

| 2X | 60° | 223 |

| 250X | 60° | 250 |

| 350X | 60° | 350 |

| 500X | 60° | 500 |

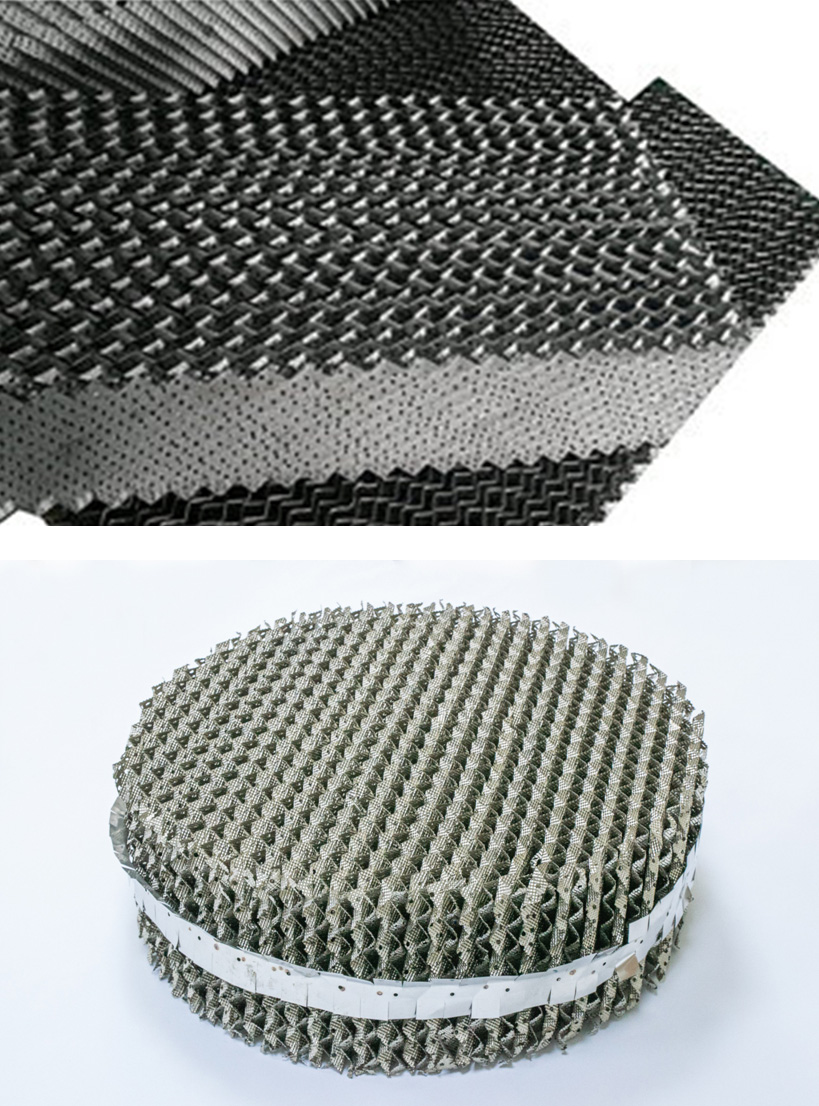

HSP

Wire Gauze Structured Packing

HSP wire gauze packing is a fabric woven from fine-diameter wire. The packing elements consist of parallel, perforated, corrugated sheets of wire mesh. This packing is successfully used in distillation service for deep vacuum and very low liquid rate applications because of the capillary effect providing an extremely wettable surface, resulting in excellent separation efficiency.

High capacity BX Plus is also available, which offers the same efficiency as BX, but a 20% lower pressure drop than BX packing.

• Provides the highest efficiency and lowest pressure drop per theoretical stage.

HSP

Grid Structured Packing

HSP grid-type packing represents the ultimate packing for structural integrity and fouling resistance. This grid-type packing is used to provide heat transfer and de-entrainment in some of the most fouling services known, such as vacuum/atmospheric crude units, cracked gas quench towers and scrubbers with fouling solids.

Its high structural strength, highly open and low pressure drop construction allow that it withstands extreme upset conditions and large vapor surges without damage. The surface of this packing drains rapidly and so there is minimal liquid hold-up, which can eliminate overheating stagnant droplets caused by coking and fouling in refinery process units.

• Optimizes heat transfer applications.

• Provides greater structured strength and fouling resistance.