Bed Limiters

THE BEST PARTNER HANBIT SOLTECH

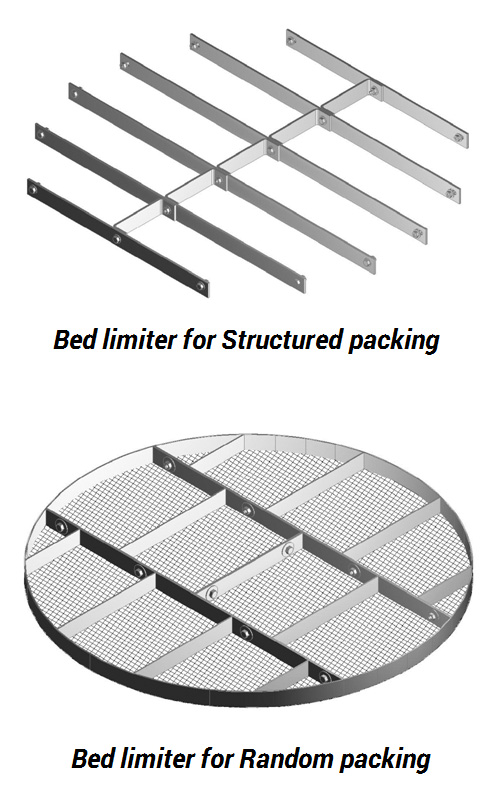

Structured Packing

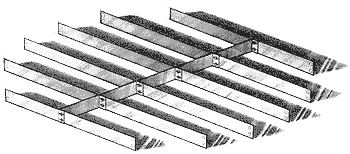

Bed limiters are recommended for use with structured packing when there is the potential for packing displacement during upset conditions. Many columns with structured packing do not need bed limiters.Random Packing

For metal and plastic random packings, bed limiters are recommended when there is the potential for sufficient vapor load to fluidize the top of the bed. There are three basic ways to prevent upward movement of random packing: bed limiters, anti-migration bars and hold-down plates.The bed limiter is the most common type. A bed limiter either sits directly on the packing or is attached to the vessel wall. Attachment to the vessel wall increases interference with the distribution pattern. The bed limiter acts as a screen to confine the packing to the defined bed.

Another method of retaining a bed of random packing is through the use of anti-migration bars at the bottom of the distributor’s gas risers.

The hold-down plate is used with ceramic or carbon tower packing to prevent breakage.

Model BLS-133

Non-Interfering Bed Limiter for Structured Packing

The Model BLS-133 is used on top of structured packing to prevent movement caused by minor vapor surges. Its design minimizes interference with liquid distribution.

Model BLR-103

Non-Interfering Bed Limiter for Random Packing

The Model BLR-103 bed limiter rests on the packing and prevents random packing from escaping. It is designed to minimize interference with liquid distribution. The bed limiter diameter is expandable to permit contact with the tower wall, which eliminates the need for wall attachments.

Model BLR-823

Bed Limiter for Random Packing

The Model BLR-823 is used on top of random packing to keep the packing from moving in the tower. Packing movement can be caused by a vapor surge or fluidizing of the bed.