Liquid-Liquid Extraction

THE BEST PARTNER HANBIT SOLTECH

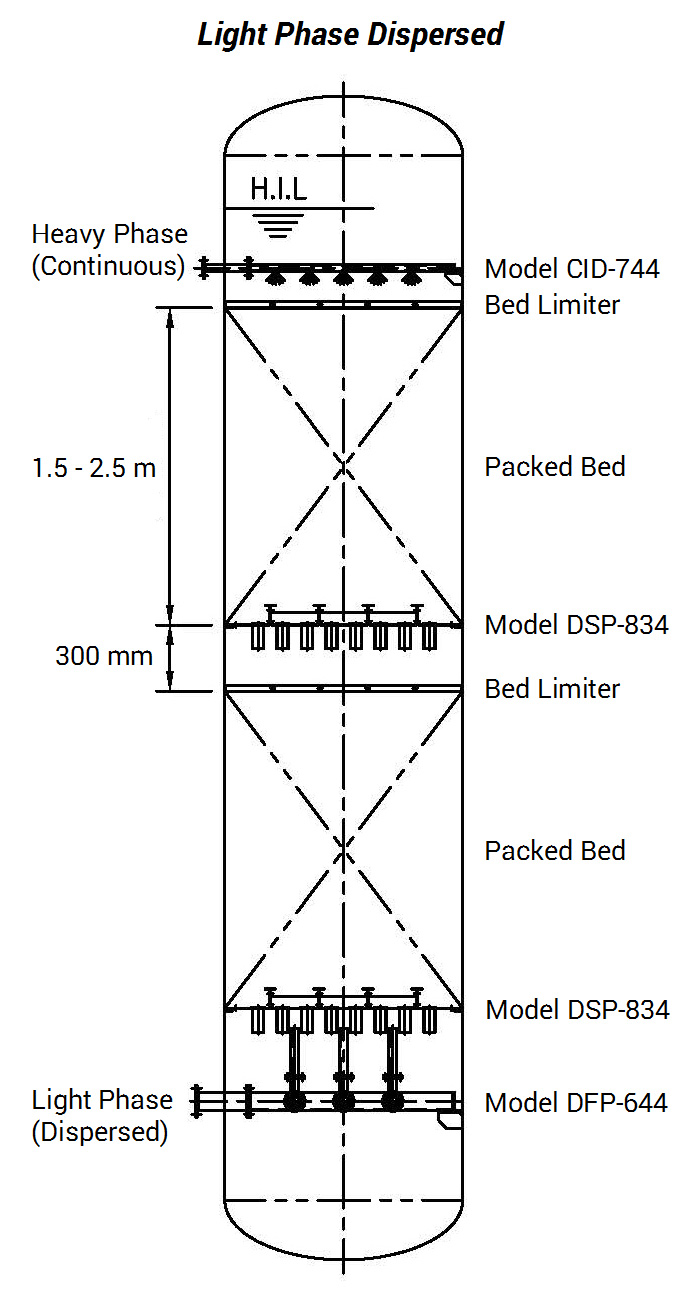

In contactors where the light-phase (feed which enters the bottom of the tower) is dispersed, packed beds are supported by the Model DSP-834 disperser/support plate.

In addition to supporting the packing, the plates allow proper dispersion or formation of small droplets which rise through the continuous phase. In breaking the dispersed liquid into small droplets, the Model DSP-834 provides maximum initial contact area between the two phases.

Because the droplets tend to coalesce in the packing, beds are typically limited to a depth of 1.5 to 2.5 m. Multiple beds, each supported by a Model DSP-834, are recommended where a total of more than 2.5 m of packing is required.

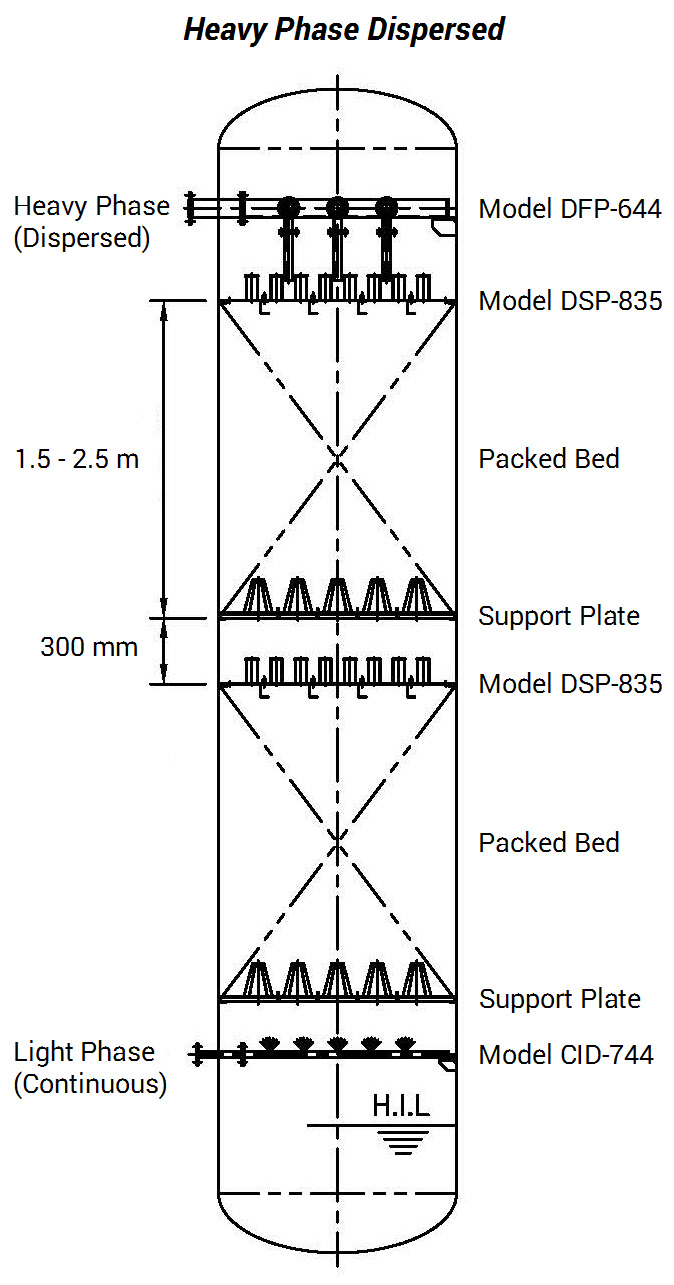

When the heavy-phase (feed which enters the top of the tower) is dispersed, the Model DSP-835 disperser plate is used above the top bed.

When multiple beds are required, the Model DSP-835 is also used to support the upper beds without a support plate and collect and redisperse the heavy-phase to the beds below. The bottom bed is supported by a conventional support plate.

The Model DSP-835, although structurally different, is hydraulically upside-down compared to the Model DSP-834. In heavy-phase dispersed contactors, the same bed depth recommendations apply as with light-phase dispersement.

※ If the entire table is not visible, you can scroll the table left and right to check the entire table..

| Model | Description | Phase |

|---|---|---|

| DSP-834 | Disperser/Support | Light dispersed |

| DSP-835 | Disperser/Support | Heavy dispersed |

| DFP-644 | Feed Pipe | Dispersed (light or heavy) |

| CID-744 | Distributor | Continuous (heavy or light) |

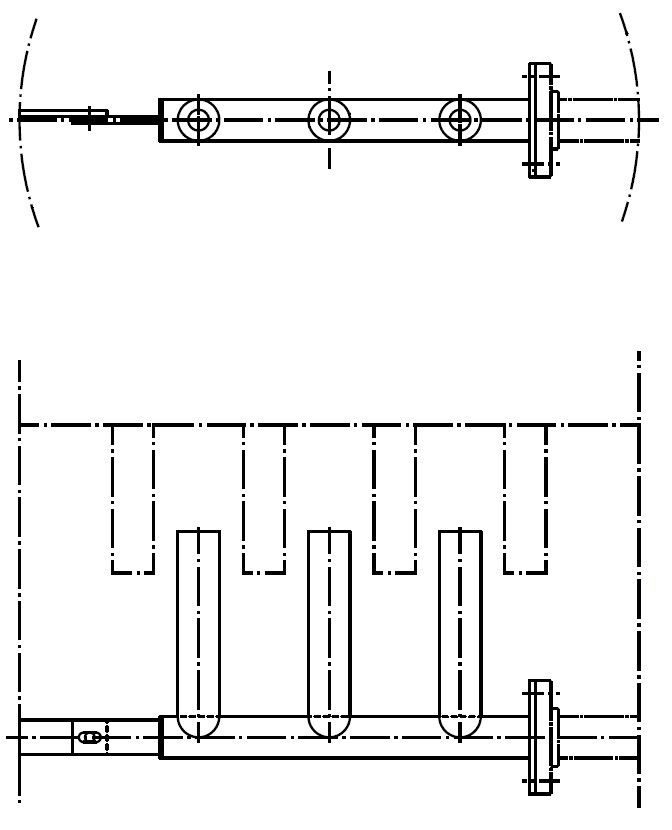

Model DSP-834

Disperser/Support Plate

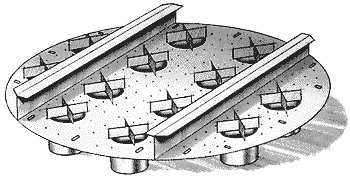

The Model DSP-834 disperser/support plate serves two purposes: to support the packed bed and to disperse the light-phase into the continuous heavy-phase. Dump tubes allow the heavy-phase to travel downward through the plate. The light-phase forms a pool under the plate and the orifices generate droplets. The plate design depends on interfacial surface tension, viscosity and differential densities. This plate also acts as a re-disperser in multi-bed towers.

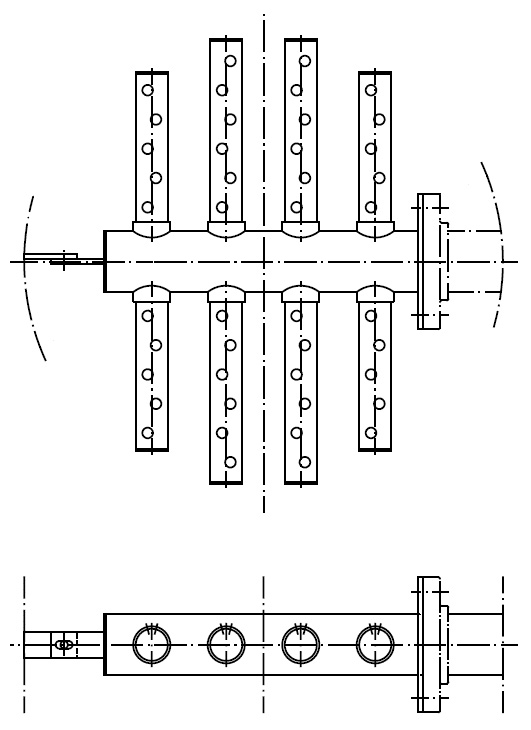

Model DSP-835

Disperser/Support Plate

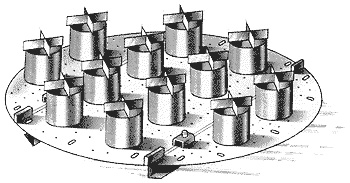

The Model DSP-835 disperses a heavy-phase into the continuous light-phase and in some cases supports the above packed bed. Riser tubes allow the light-phase to pass up through the plate. The heavy-phase forms a head on the top of the plate and orifices generate droplets. The plate design depends on interfacial surface tension, viscosity and differential densities.

Model DFP-644

Dispersed-Phase Feed Pipe

The Model DFP-644 feed pipe controls velocity of the dispersed phase flow onto the disperser plate. It is important to prevent excessive turbulence at the phase boundary at the plate. This feed pipe controls feed velocity and correctly positions the discharge points to minimize disturbance. If this requirement is not met, this could lead to maldistribution, loss of dispersion, and premature flooding.

Model CID-744

Continuous-Phase Inlet Distributor

The Model CID-744 inlet distributor controls velocity of the continuous phase flow into the tower. Proper control of velocity is important to prevent excessive disturbance of the heavy/light interface, which could lead to carry-over of the dispersed phase. The maximum continuous phase flow should be less than 18.3 m3/hr/m2.