Feed Devices

THE BEST PARTNER HANBIT SOLTECH

• Liquid only

• Liquid and vapor above a packed bed

• Vapor only below a packed bed

• Reboiler returns

The selection of liquid-only feed devices, which are required as pre-distributors, depends on the type of distributor and on turndown needs.

For liquid and vapor feed devices above a distributor, the selection depends on the type of distributor, flow rates, type of flow at feed(flashing or suppressed flashing), turndown necessary, column height needed for flashing vapor distribution and mixing of the inlet liquid with the overhead liquid. In all cases, separating the two phases is a primary concern.

Two factors must be considered in choosing the proper device for a vapor only feed below a packed bed.

1. Kinetic energy of inlet vapor

2. Vapor composition (mixing of the inlet vapor with the rising vapor)

To determine the type of feed device required for a reboiler return, the first step is to consider the kinetic energy. After that factors such as feed nozzle size and arrangement, flow rates, and type of reboiler should be considered as well.

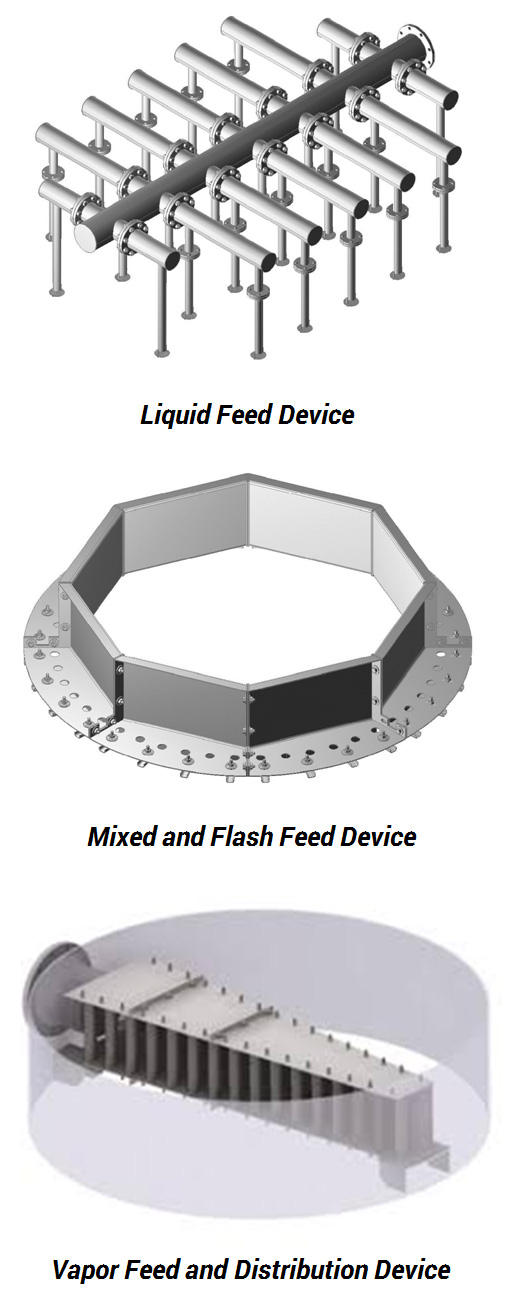

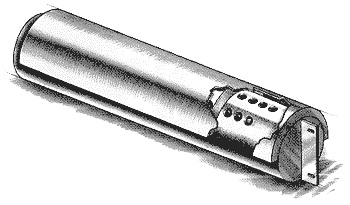

Model HFP-119

High Performance Liquid Only Feed Pipe

The Model HFP-119 is recommended for use when liquid is fed from outside of the column onto a distributor or redistributor. This type of feed system meters flow to one or more feed areas through head pipes in conjunction with lateral branches, downpipes, and/or parting boxes or pre-distribution channels. That feed directly to the distributor which can eliminate an excessive turbulence and horizontal flow velocity in the distributor.

Model TFP-719

Liquid Only Feed Pipe

The Model TFP-719 is a feed system of head pipes and downpipes. This type of feed pipe is recommended to use in conjunction with a pre-distributor or a parting box when liquid is fed directly onto distributor or redistributor.

• Liquid only feed (less than 1% volume vapor)

• Piping system of headers and downpipes

Model FFG-755

Flashing Feed Gallery

The Model FFG-755 is a two-phase feed device fed by a tangential inlet tower nozzle or a radial nozzle with a flow deflector. A gallery below the inlet nozzle collects liquid into a pool, allowing the vapor to disengage. The liquid then falls directly to a distributor or into a pre-distributor or a parting box. The gallery type is commonly used in foaming systems and larger-diameter columns.

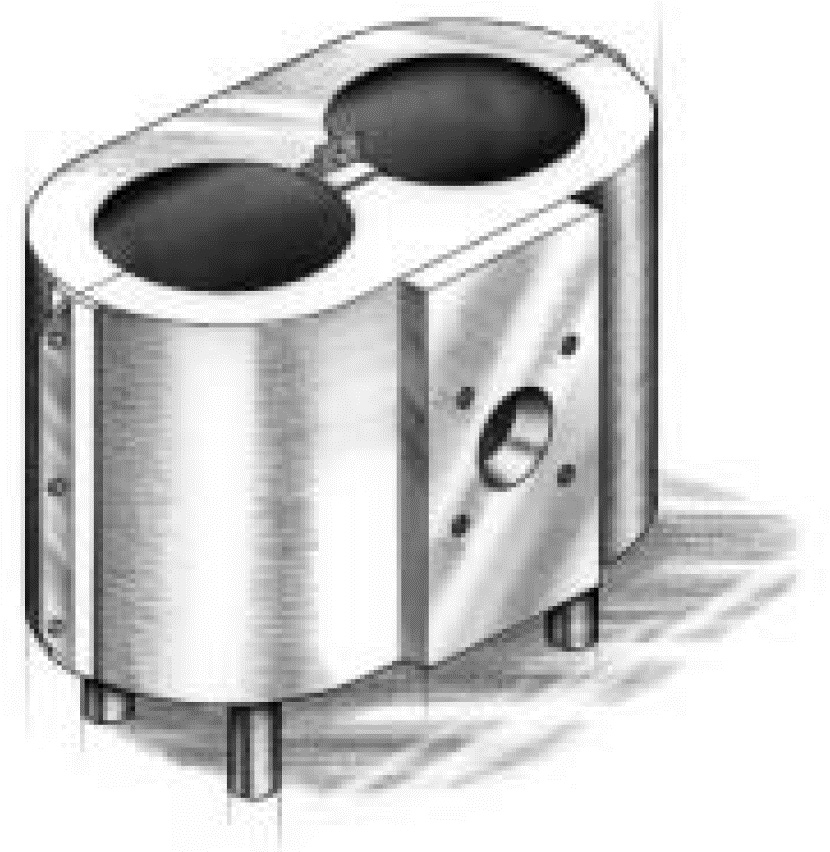

Model FFC-855

Flashing Feed Chamber

The Model FFC-855 is a two-phase feed device which is attached to a radial inlet. The feed is centrifuged in the chamber, separating the phases: vapor out the top and liquid out the bottom to a distributor below. This model is most suitable for small columns.

Model FFP-955

Flashing Feed Pipe

The Model FFP-955 is used to separate a two-phase feed when the inlet flow is in a separated flow region, i.e. the liquid and vapor of flashing feed are easily disengaged. After the disengagement, the liquid flows to the outer chamber where it is metered to desired points on the distributor below and the vapor is released from the upper area of the pipe so as not to disrupt the liquid flowing onto the distributor.

• Column diameters : greater than 1200 mm

• Two-phase feed that readily disengage

Model VID-196

Vapor Inlet Diffuser

The Model VID-196 is used where the incoming flow is vapor only and the flow energy is excessive, causing vapor maldistribution to the bed above. This device is not a vapor distributor. It reduces the flow inertia, which allows proper distribution. The Model VID-196 meters the vapor uniformly out the upper area of the pipe and the shroud, then directs it down each side of the pipe.

• Column diameters : greater than 1200 mm

• Vapor only feed (extreme inlet velocities)

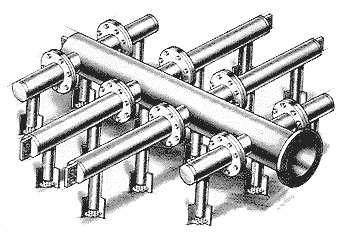

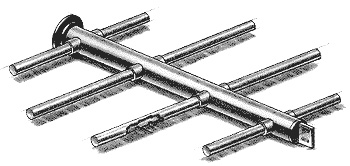

Model PVD-198

Pipe-Arm Vapor Distributor

The Model PVD-198 ladder pipe vapor distributor is used when the feed requires uniform distribution over the tower area. Typical applications include introduction of a vapor feed at the bottom of the tower into a very tight space or introduction of a vapor feed between beds which differs in composition or temperature and needs mixing with the vapor from the bed below.

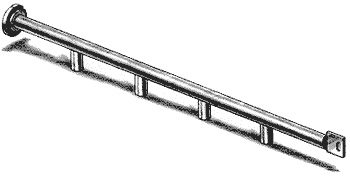

Model VED-194

Vane-Type Evenflow Inlet Distributor

The Model VED-194 vane-type inlet distributor is commonly used for introducing high energy vapor or high velocity mixed phase feeds by a radial inlet. The curved vanes reduce the momentum of the inlet feed in a controlled manner, and the tapered construction design provides a uniform feed distribution in each section. Designs are available for operation in most vapor/liquid flow regimes.

• Column diameters : greater than 1200 mm

• Vapor only or mixed phase feed