High Performance Trays

THE BEST PARTNER HANBIT SOLTECH

We have the ability to design and manufacture trays and hardware to revamp equipment originally provided by other mass transfer manufacturers.

Our T-Valve high-capacity trays and fouling resistant P-Valve trays are enhancing performance in a broad range of services:

Refining Applications

• Atmospheric crude fractionators• FCCU main fractionators

• Coker fractionators

• Hydrocracker fractionators

• Gas oil stripping

• Slurry stripping

• Hydrotreater product stripping

• Deisobutanizers and debutanizers

• Alkylation isostrippers

• Amine regenerators

• Naptha, gasoline and reformate stripping

• Gas plant and light ends distillation

• H2S and CO2 absorbing

• Sulfolane stripping and recovery

• Waste water and sour water stripping

Chemical/Petrochemical Applications

• Olefins plant distillation• Caprolactam distillation

• Ethanol distillation

• VCM distillation

• Dichlorobenzene distillation

• HCN distillation

• Acetic acid distillation

• Cumene distillation

• Butadiene distillation

• Acrylonitrile and acrylic acid distillation

• Formaldehyde absorption

• Nitric acid absorption

• Phosgene stripping

• Alcohol stripping

• Process gas stripping

• Waste water stripping

• Organics stream stripping

• Solvent recovery

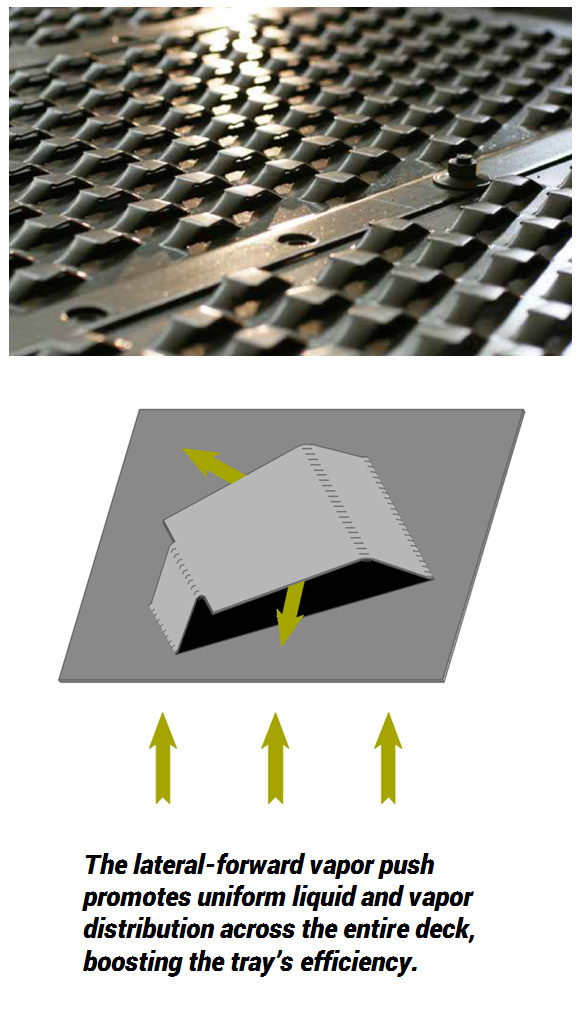

M-Valve Tray

Fixed M-Valve features a crude valve cover that is punched up from the tray deck. When the valve cover is punched from the tray deck, its shape must be the same as that of the punched orifice. The fixed valve is a low-cost stationary assembly which imitates the shape of a valve. This fixed valve feature provides uniform liquid flow across the entire bubbling area for added capacity.

Fixed M-Valve trays with tapered shape valve offer lower entrainment compared to sieve trays due to the lateral-forward vapor orientation while at the same time protecting the tray deck from fouling.

The fixed valve was introduced later as a less expensive and lower maintenance alternate with some sacrifice of turndown. Modern designs have minimized this turndown difference.

Advantage

• No more valve leg wear and popped, stuck valves

• Higher capacity than sieve or conventional valve trays

• Lower pressure drop than sieve or conventional valve trays

• Better turndown ratio (3:1) than sieve trays

• Lower entrainment

• Suitable for fouling services

• High mechanical strength

P-Valve Tray

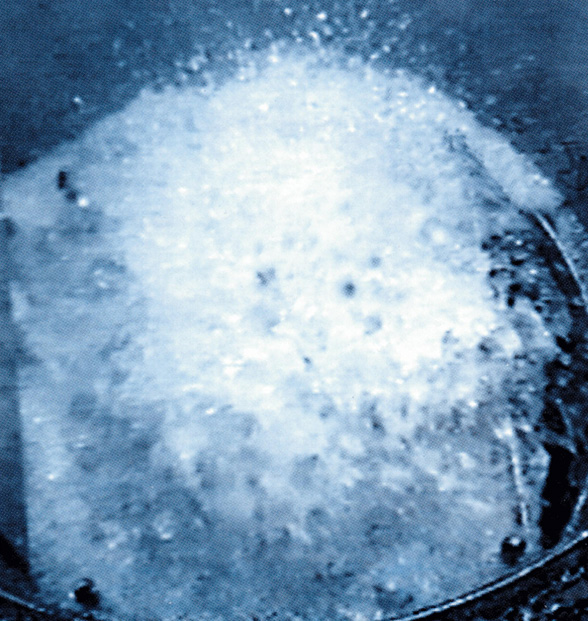

P-Valve tray is a high performance tray that combines the best characteristics of a moving valve tray and a fixed valve tray. Unlike fixed valves punched from the deck, the P-Valve features a cover that extends beyond the opening for improved vapor deflection. This feature significantly reduces spray height, which translates into greater capacity than other fixed valves for a given flow rate. The P-Valve also allows operators to achieve turndown ratios equal to those possible with single-weight moving valves.

The fixed design eliminates the likelihood of stuck or popped valves commonly associated with moving valves, and promotes uniform vapor distribution and more even spray height. This keeps tower running at peak efficiency longer, without worry about surprise shutdowns due to valve failure.

P-Valve trays can replace conventional trays on a one-for-one basis using the existing tray supports and the same hardware.

Advantage

• Improved capacity over sieve or conventional valve trays

• Lower pressure drop than sieve or conventional valve trays

• Turndown equal to typical floating valve trays

• Better performance than conventional valve trays

• Reliable and low-maintenance design

• Non-fouling and wear-resistant design

• Easy and economical installation

※ If the entire table is not visible, you can scroll the table left and right to check the entire table..

| Features | Conventional Valve | P-Valve | Provides |

|---|---|---|---|

| Valve Design | Movable round valve | Tapered design fixed valve | Eliminating the likelihood of stuck or popped valves associated with moving valves. |

| Direction of Liquid Flow | No directional flow | Directional push to liquid | Improving efficiency by eliminating dead spots and backmixing. |

| Fouling Tendency | Low to moderate | Excellent fouling resistant | Keeping the tray free of debris. |

| Vapor Distribution | Non-uniform vapor distribution | Uniform vapor distribution | Increasing capacity by 10 to 15% over conventional valve trays while maintaining or improving efficiency. |

In fact, the P-Valve tray provides increased capacity, equal or greater efficiency and decreased pressure drop when compared to conventional valve trays.

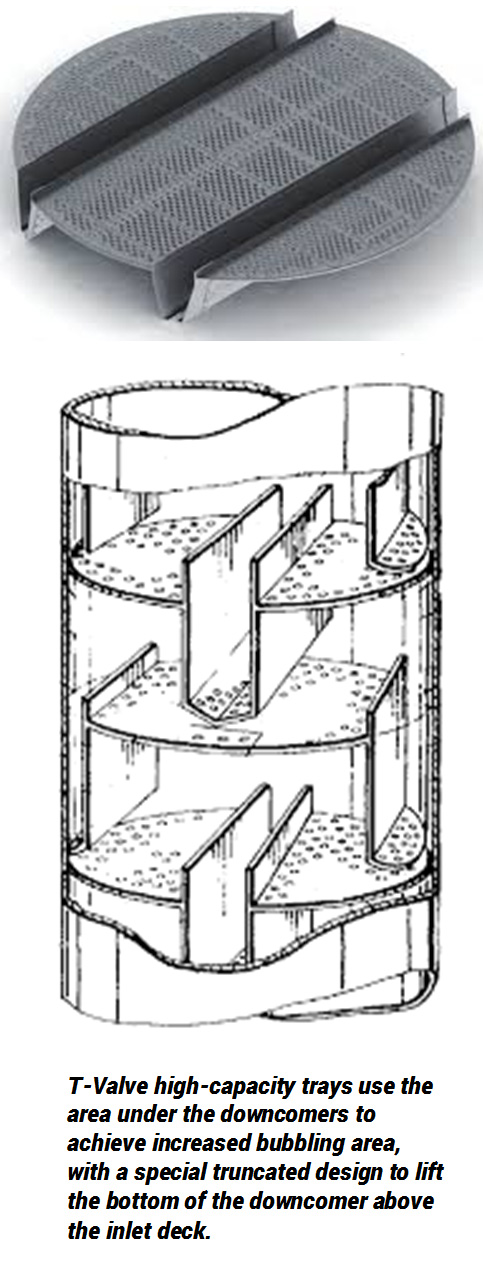

T-Valve Tray

The innovative downcomer design of T-Valve tray significantly increases the tray’s active bubbling area, and also includes the P-Valve that optimizes bubbling and liquid flow across the tray deck. The combined effect of increased bubbling area and enhanced valve design provides greater capacity than conventional valve trays. The downcomer design also increases the length of the flow path across the deck, boosting the tray’s efficiency.

T-Valve can replace existing trays on a simple “one-for-one“ basis without sacrificing separation efficiency and so this characteristic eliminates the need for expensive tower attachment modification.

Advantage

• Substantially greater capacity than conventional valve trays

• Special truncated downcomer design maximizes vapor handling capacity

• Valve design promotes uniform bubbling throughout the tray deck for improved capacity and efficiency

• Lower pressure drop than conventional valve trays

• Mechanically robust design

• Installation uses existing tower attachments