THE BEST PARTNER HANBIT SOLTECH

Our random packings are available in a wide range of material.

For the metal random packing :

• Carbon Steel• Stainless Steels (including Austenitic, Ferritic, Martensitic, Duplex)

• Aluminum

• Nickel and Nickel Alloys

• Copper and Copper Alloys

• Titanium and Zirconium

For the plastic random packing :

• Polypropylene• Polyethylene

• PVC

• CPVC

• PVDF

• ETFE

• PFA

HMTP

High Performance Metal Random Packing

HMTP combines the high void fraction and the well-distributed surface area of the Pall ring with the low aerodynamic drag of the saddle shape. Compared to the Pall ring, it provides a more open shape and improved liquid spread, while incorporating adequate mechanical strength and entanglement resistance. HMTP is available in metals only.

• Provides greater capacity and efficiency than fractionation trays and other random packings.

• Exhibits approximately 40% lower pressure drop than equal-sized pall rings.

• Minimizes liquid residence time through low liquid hold-up.

M-Ring

High Performance Metal Random Packing

M-Ring is similar to the Pall ring, but have an aspect ratio (height to diameter ratio) of 1:3, compared to 1:1 in the Pall ring. The lower aspect ratio orients the particles with their open side facing the vapor flow, thus reducing friction, and exposing more surface to mass transfer.

• Low aspect ratio provides higher capacity, lower pressure drop and better fouling resistance.

• The highly exposed surfaces provide better liquid distribution and higher efficiency.

※ If the entire table is not visible, you can scroll the table left and right to check the entire table.

| Size, no. (#) | Surface Area, ㎡/㎥ | Voids, % |

|---|---|---|

| 0P | 328 | 95 |

| 1P | 250 | 96 |

| 1.5P | 190 | 96 |

| 2P | 151 | 97 |

| 2.5P | 121 | 97 |

| 3P | 103 | 98 |

| 4P | 71 | 98 |

| 5P | 50 | 98 |

M-Ring

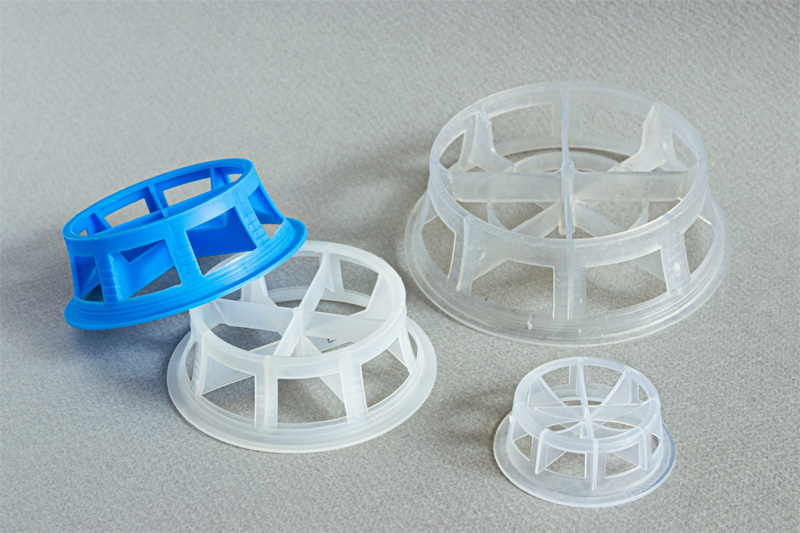

High Performance Plastic Random Packing

Plastic M-Ring is made of chemical corrosion resistant plastics. They are preferred over metal materials for their chemical resistance and economical advantage in corrosive applications. The open structure allows for easier flushing of solids by the liquid through the bed, which prevents fouling.

• Low aspect ratio increases capacity and reduces pressure drop.

• Lightweight, ring and spoke construction allows for use in deep beds.

Pall Ring

Metal Random Packing

Pall ring is developed by cutting windows in the Raschig ring and bending the window tongues inward. This opened up the ring, lowered its friction, and improved packing area distribution, wetting, and distribution of liquid. Pall rings remain one of the most commonly used tower packings in industry.

• Provide higher capacity and efficiency and lower pressure drop than Raschig rings.

※ If the entire table is not visible, you can scroll the table left and right to check the entire table.

| Size, inch | Surface Area, ㎡/㎥ | Voids, % |

|---|---|---|

| 5/8 | 360 | 93 |

| 1 | 205 | 94 |

| 1 ½ | 130 | 95 |

| 2 | 105 | 96 |

| 3 ½ | 66 | 97 |

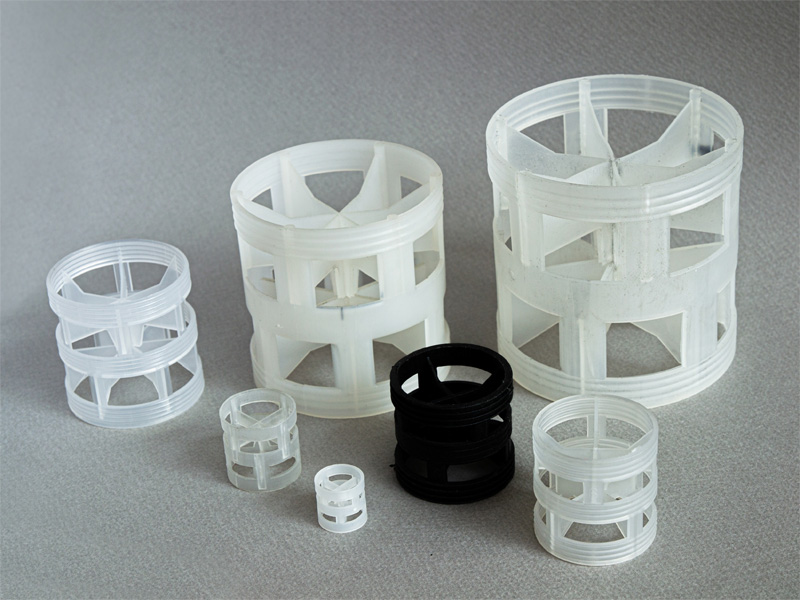

Pall Ring

Plastic Random Packing

Plastic Pall rings are used extensively in the chemical process industry with low to moderate operating temperature and can offer an economical advantage over metal materials. Unlike Raschig rings, the walls of Pall rings are open and the interior of each ring has diametrical ribs. The windows allow full access to the interior for both gas and liquid, while the ribs provide structural strength and additional surface area for gas-liquid contact.

• The high percentage of free space maintains uniform liquid distribution.

Raschig Ring

Metal Random Packing

Raschig ring is the first ring type packing applied in mass transfer. The height of the ring is equal to its diameter. The rings are cut from pipes, but in case of metal they may also be rolled from metal strips. Raschig rings are proven in a wide range of mass transfer applications.

• The oldest, cheapest, and previously most widely used packings.

※ If the entire table is not visible, you can scroll the table left and right to check the entire table.

| Size, inch | Surface Area, ㎡/㎥ | Voids, % |

|---|---|---|

| 3/8 | 528 | 82 |

| 1/2 | 400 | 84 |

| 5/8 | 328 | 86 |

| 3/4 | 266 | 88 |

| 1 | 203 | 85 |

| 1 ½ | 128 | 90 |

| 2 | 95 | 92 |

| 3 | 66 | 95 |

Raschig Ring

Ceramic Random Packing

Ceramic Raschig rings have excellent acid and heat resistance. These should be considered in any environment where it can be handled only with expensive metal alloys under corrosive conditions, or where plastics are not allowed due to temperature conditions.

• High chemical stability.

• Excellent heat endurance.

• Acid, alkali, salt and various organic solvents resistance.

※ If the entire table is not visible, you can scroll the table left and right to check the entire table.

| Size, inch | Surface Area, ㎡/㎥ | Voids, % |

|---|---|---|

| 1/4 | 789 | 60 |

| 3/8 | 440 | 60 |

| 1/2 | 330 | 65 |

| 3/4 | 243 | 69 |

| 1 | 190 | 72 |

| 1 ½ | 121 | 73 |

| 2 | 92 | 74 |

| 3 | 62 | 77 |

Raschig Ring

Carbon Random Packing

Carbon Raschig ring is a cylindrical packing of graphite material. They are resistant to high temperature, acid and alkali. HST offers carbon Raschig rings for processes where ceramic packing is not viable.

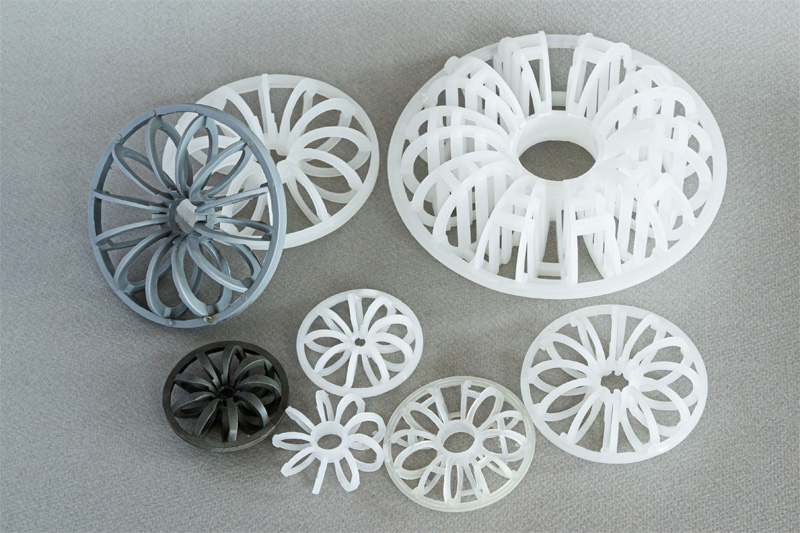

Starflake

High Performance Plastic Random Packing

Starflake high-performance random packing offers superior separation efficiency and capacity in environmental applications, such as scrubbing and stripping. The low aspect ratio, even lower than that of M-Ring, orients the Starflake particles with their open side facing the vapor flow. This reduces friction and permits good liquid drainage from the ribs of the packing.

• Optimizes absorption and stripping towers.

• Combines high capacity with high efficiency in one packing size.

• Provides lower pressure drop than 90 mm plastic packings.

• Exhibits greater efficiency than other 38 mm plastic packings.

Super Saddle

Plastic Random Packing

The smooth edges of Saddle packing were scalloped in the Super saddle and holes were inserted. These changes promote drainage of liquid, eliminate stagnant pockets, and provide more open area for vapor rise. Super saddles enhance internal gas and liquid distribution, allow higher capacity and maximize mass transfer efficiency.

• Provide higher efficiency than plastic Pall rings and maintain at least equal capacity.

• The scalloped edges immobilize the packing within the bed, which maintains packing free space and lowers column pressure drop.

※ If the entire table is not visible, you can scroll the table left and right to check the entire table.

| Size, no. (#) | Surface Area, ㎡/㎥ | Voids, % |

|---|---|---|

| 1 | 207 | 90 |

| 2 | 108 | 93 |

| 3 | 89 | 94 |

Super Saddle

Ceramic Random Packing

For optimal performance, the Super saddle offers better liquid/gas contact and lower pressure drop than standard saddles of similar size. The product features a unique scalloped edge that permits maximum usable area for liquid/gas contact and minimal resistance to flow through the bed.

• The No.1 Super saddle provides 35% lower pressure drop and slightly improved mass transfer efficiency than standard saddles of similar size.

• The No.2 Super saddle provides approximately 25% lower pressure drop with 5 to 30% greater mass transfer efficiency than standard saddles of similar size.

T-Ring

Plastic Random Packing

T-Ring packing has large effective interfacial area of mass and heat transfer efficiency for gas absorption, stripping, scrubbing and air conditioning. Excellent liquid distribution and uniformity are obtained, because of a large number of branching and junction, in addition to curve structure of the packing.

• Large effective interfacial area without dead space.

• Large void fraction enables to lower pressure drop and to minimize tower diameter.

• Geometric structure of the packing offers good distribution.

Saddle

Ceramic Random Packing

Saddle was developed from the Berl saddle that is the original type of saddle packing. Their aerodynamic shape is giving a lower pressure drop and higher capacity than Raschig ring. Saddles, the mass transfer industry standard for ceramic packing, are the packing of choice for reliable corrosion-resistant performance.

• Provide approximately 56% greater capacity than Raschig rings.