Support Plates

THE BEST PARTNER HANBIT SOLTECH

• Allowance should be made for absorbing the shock of pressure surges, deterioration due to corrosion, and any additional weight not separately supported.

• The support, and any beams used, should be of such a design that vapor distribution is not adversely affected.

• Liquid leaving the base of the packed bed must be discharged in such a manner as to avoid any deterioration in vapor distribution.

• Sufficient free area should be provided to permit free flow of downcoming liquid and rising gas.

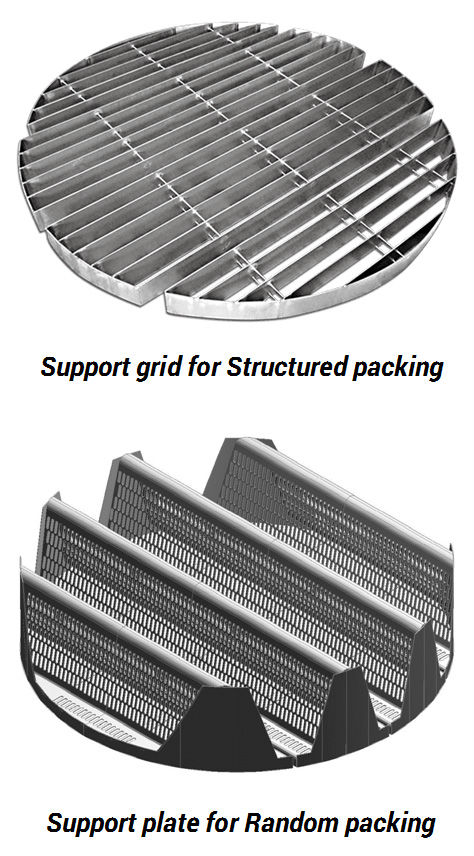

Structured Packing

Supporting a structured packing is somewhat simpler than supporting random packing because the integral nature of the structured packing physically allows support by an open grid. The major design criteria is minimization of the grid cross-sectional area while providing sufficient strength.Random Packing

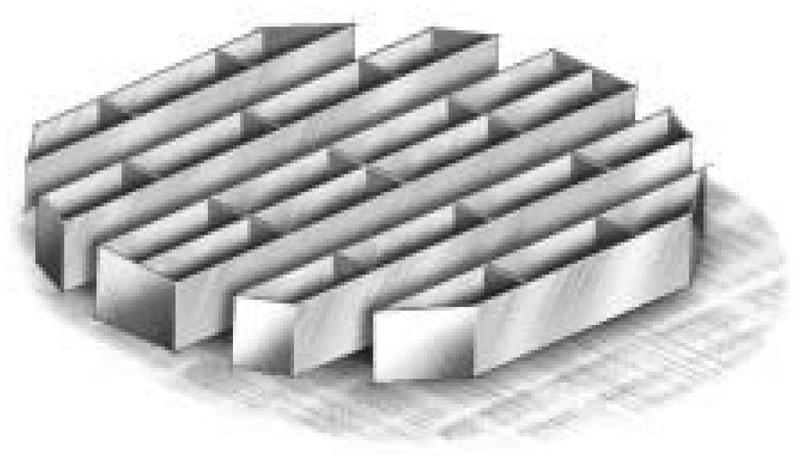

Random packing uses a gas-injection type support plate that provides separate passageways for gas and liquid so both phases do not compete for the same opening. Unrestricted flow of both phases minimizes pressure drop across the plate. This is done by providing gas inlets above the liquid head, preventing excess liquid build-up. The support plates are designed to retain the various packing sizes while not restricting the capacity of the packing.Model SGS-134

Support Grid for Structured Packing

The Model SGS-134 is used to support either metal-sheet structured packing or wire-gauze packing. The support grid is designed so that gas and liquid can pass freely and uniformly through the packing without limiting the capacity of the packing.

Model SPR-804

Gas Injection Support Plate for Random Packing

The Model SPR-804 is used to support random packing in towers greater than 900 mm ID. The plates are a gas injection type which allow for separate gas and liquid passage. This model is recognized as the typical style due to its high open area and mechanical strength.

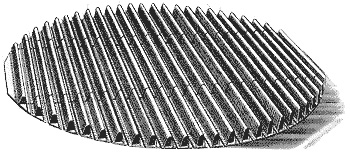

Model SPR-818

Gas Injection Support Plate for Random Packing

The Model SPR-818 is generally used to support random packing in towers less than 900 mm ID. The plates are a gas injection type which allow for separate gas and liquid passage. This model combines high free area with excellent mechanical strength.

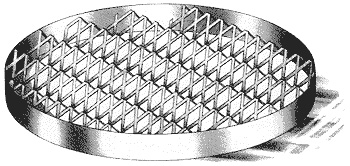

Model SPR-809

Light Duty Support Plate for Random Packing

The Model SPR-809 is a corrugated support plate to use for towers between 100 – 895 mm ID supporting metal, ceramic or plastic random packings. This light-duty support plate should be used only where bed loads are not high and corrosion problems are not severe.